Our reference book and the guide to automobile and the armored vehicles of the Second World War based on documents and photographs from our own archives.

Panzerkampfwagen V (PzKpfw V) Panther WW2 German medium tank (Kubinka museum Patriot Park collection, Russia). Third Reich the service list name was Sd.Kfz. 171.

The Soviet classification: German heavy tank T-V “Panther” or PzKpfw V Ausf. G (requires verification), the year of issue 1943, the serial model. The Panther tank was developed and produced in Nazi Germany since 1943 and took part in the Battle of Kursk and later in Europe.

PzKpfw V Panther tank photo gallery

Archival photographs show the Panther tank immediately after being painted in historical color in 2003, before and after its restoration in 2005 to running condition.

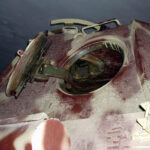

- PzKpfw V cannon and turret (2008 archives)

- Tank sprocket and wheels in a checkerboard pattern (2003 archive)

- Tank turret and commander’s cupola (2008 photo)

- Tank sprocket and wheels in 2008

- Rear view of the Panther tank (2003 photo)

- Rear hatch on a tank turret (2005 photo)

- Open hatch to a tank turret (2005 photo)

- PzKpfw V muzzle brake

Panther tank the tactical and technical characteristics:

- The weight 45.5 t., crew 5 people.

- The overall dimensions in mm (length x width x height): 6880 х 3430 х 3100

- Weapons: 1 cannon by the caliber – 75 mm. and the ammunition 79 shots,

- 2 machine guns by the caliber 7,92 mm. and the ammunition 4200 shots

- The armored protection – the corps front- 80 mm., the turret front – 110 mm.

- The Engine power is 700 hp, the Maximum speed is 46 km/h, Cruising on the highway — up to 180 km

Panther tank design features:

The Chassis – original with the rolled armory plates, welded and riveted by rational angles.

The armament – 75 mm long-barreled gun installed in the turret which the rotation by the hydraulic drive. One machine gun is paired with a cannon, and a second MG on the ball bearing front hull.

The stern of the turret there is a large hatch for the entry and exit of the crew, there are also the individual hatches for the driver, the gunner and the commander.

The chassis includes 8 (for one side) of the rollers arranged in staggered rows and one support roller, the torsion bar suspension. The Panther tank is adapted for the under water driving.

The serial number found on the fuel cistern is 887/44, perhaps is N 887 of the vehicle, produced in 1944at one of the factories.

The Panther tank was captured by the Red Army as a trophy at the end of World War II. No exact information about the location of the seizure was found (see description of the destruction of the archive in the early 90s). There is almost no external damage to the tank – only minor traces of shrapnel on the starboard side. Serial number found on the fuel tank of tank 887/44. That is, presumably this is the 887th tank, produced in 1944 by one of the factories. This statement also requires verification, so we post below with the serial numbers of another part of the tank corps near the gasoline tank, where the numbers are visible 31 * 1814 PG519 or A?0PG 1 1064 PG 526 (or 0).

The tank also retained traces of Zimmerit ointment.

Repair and restoration of a Panther tank in Kubinka workshops, Part 1.

During World War II, the Red Army captured this Panther tank in the excellent working condition as a trophy. When studying the tank, Soviet specialists, as usual, used “a sledgehammer and dirty curse words,” and in the process they broke the magneto. Further, from 1945 to 1972, the tank was outdoors in the harsh Russian conditions of the rain, snow, and frost. Since 1972, the tank was into a hangar, under a roof, but without heating in winter and the rusting process continued. Starting in 2001, on the instructions from the management of the tank museum, a special team of the volunteers began repairing some German and Soviet tanks for free. The work took place, mainly on weekends, by the civilians, mainly the amateur scale models. After the restoration of the Soviet light tank T-70, the German Panzer IV, the next in the line was the Panzer V. In 2005, the Panther was restored to the running condition and was demonstrated for the visitors. During the filming of the Russian film “Father” about the Second World War on the territory of the Kubinka training ground, according to one version, the gasoline turned out to be of the poor quality or contained the garbage, as a result of which the Panther again became faulty. Additional repairs were required and the tank became operational again. The Panther has been used several times at the festivals, the military history reenactment shows the fragments of World War II battles to promote the national patriotism. Once there was a real WW2 fighting, an unequal duel between the Soviet T-34 tank (76 mm) and the German Panther. The Soviet tank accidentally emerged the victorious and a film was made based on this plot. During the holidays, this episode of the victory of the Soviet T-34 over the German Panther was shown several times in the Kubinka tank museum. After a change of the commander of the tank museum, as well as major organizational changes, Panther’s participation in the reconstruction ceased, the tank itself was moved to Patriot Park. We publish below archival photographs of the double restoration of the Panther, and in another section a gallery and description of the battle reenactment.

- Kubinka Tank Museum before the construction of hangars

- Former secret library and archive 38NIIII (center) and hangars (2006)

- Panther in a restoration hangar (2005)

- One of the rooms of the Soviet-era hangar with the Panther (2005)

- Volunteers repairing the engine

- Repair of the Panther after filming

- Fine dust in the air during repairs

- Wheels and track in the mud after filming

- Dirty trucks after filming at the shooting range

- Roman K, repairman and WW2 reenactor

- Gunner’s seat in Soviet protective green paint

- Gun rotation mechanism

- Triplex of the tank driver

- Driver’s seat, control pedals, clutches, brake discs

- Machine gunner’s place

- Mechanisms and mounting stand

Initial repair of a PzKpfw V Panther in the repair rooms of the tank museum by a team of volunteers in 2005. Restoration of the Maybach engine ignition system, Bosch magneto, electric ignition. Team of repairmen – Roman A., Vitaly F., Alexander A. (scale models master), Evgeniy M. and others.

Kubinka tank museum PzKpfw V Ausf. G “Panther” restoration the official chronicle

The first study of the tank’s completeness and restoration attempts began in the 90s. The tank had a large percentage of original internal parts, but some parts are missing: a hydraulic drive for turning the turret, seats for the driver and gunner, surveillance devices, etc. It was not possible to determine how long the PzKpfw V tank was in the operation. The tank’s original battle painting and the tactical markings have not been found. Fractures of the Zimmerit coating showed that the tank was a standard factory “yellow-sand” color. To preserve the remains of the original Zimmerit coating, the paint was not removed. The delay in restoring the Panther was due to the complexity of the repairs. The project was started when the technical possibility arose to work with heavy armor plates on the roof of the engine compartment. In February 2004, the Panther from pavilion number 6 was moved for restoration to the repair building, in a special box, next to the T-34. The tank’s top armor plates were removed and work slowly began to clean the interior, with the Panther’s carburetors removed for the cleaning and adjustment. One of the two Bosch magnetos was damaged. Then they disassembled the engine to dismantle it and fully inspect it. After removing the upper armor plates, the radiator blocks and fuel tanks were removed from the Panther. Concerns about the condition of pipelines and fuel lines were completely confirmed. Fuel lines crumbled into dust, and some of the pipes under the radiator groups were rusted through. The removed fuel tanks and radiators were cleaned and painted. The fan group was disassembled and inspected – it turned out that the fan clutches were damaged, but in general the drives were in good condition… After removing the armor plates and external parts, the Panther was moved by a BREM tractor out of the box and the tank engine was dismantled. The low degree of safety of the pipelines running along the bottom of the engine was confirmed. The engine, however, looked very good with no external damage. After receiving a complete manual for the Panther engine from abroad, restoration work began.

The removed engine was restored externally and then all the attachments and pan were removed. An analysis inside the engine showed that the tank almost never drove. A version was put forward that the tank was captured on a railway platform (or storage place). This version explains the Panther’s almost complete lack of combat damage. The discovery was the absence of an inertial starter – in its place there was a mechanism for manually turning the engine – for an external starting device, inertial or gasoline. When this device is absent, the engine can be easily turned by one person, but at a very low speed. The starter and generator, which traditionally turned out to be Bosch, were removed and inspected. On the generator, we cleaned off the rust on the contact surface and on the cooling fan. In Germany, a Panther magneto was purchased at an auction in a non-working condition (the previous owners disassembled it and lost the adjusting rings). This magneto served as a “repair kit”, a donor for the destroyed original Panther magneto. The inscription “BMW” was found on the tank switch tap. The tank’s fuel pumps were removed and carefully adjusted.

The oil cooler required a lot of attention – over many years the oil in it caked, hardened and turned into grease. We washed and blew with high pressure air. The same “solid oil” could end up in the engine lubrication channels; the oil system was flushed (injected) with oil under pressure, and it was made sure that the oil was supplied to the crankshaft and other lubrication points.

On October 23, 2004, using available means (BREM tractor) and a purchased hydraulic lift, in just one hour, the engine, after partial disassembly and detailed examination, was installed back into the Panther’s engine compartment. Until the end of the summer of 2005, work was carried out on the final repair of the engine compartment in the tank. Cooling system pipes were laid and air filters were restored. On July 4, 2005, the first test start of the engine took place. The engine worked successfully, and a week later, after checking all systems, the start was repeated. Work then began to restore the original control panels. Original instruments, buttons and switches were purchased in Germany, and the control panel was restored as close as possible to the original. The restoration of the hydraulic drives of the control system began, and painting of interior parts began. In the fall of 2005, work was completed with final painting of individual parts inside the tank, completion of electrical wiring assembly and testing of the PKP (planetary gearbox) and hydraulic drives of the control system. Unfortunately, during the assembly process, it turned out that unidentified persons had stolen parts of one of the hydraulic cylinders of the control system: someone, presumably on Tankman Day, took the opportunity to disconnect a rare part in the light of burning paper, dropping some of the fastener parts into the clutch in the dark. It took three weeks to make the new parts. By the beginning of winter, the control panel, radio frame, central control unit for electrical wiring and some other devices were installed in their place, and part of the tank turret was painted. In the process of painting the tank turret and test scrapings on the hull, the details of the tank’s painting became clear. The turret of the Panther tank was painted with white paint over red primer paint. After painting with “primer,” the tank’s hull was covered with sand “dunkengelb,” and only then, with the assembled interior parts, was painted white by the Germans “along the waterline,” that is, to the level (of the tank turret) and the casings. It is interesting that if in the turret the white color goes directly on top of the primer paint, in the tank hull (hull) it is placed on top of the sand paint. The control panel cover on the reverse side retained the original Panzergrau gray color. On December 3, a control start of the engine took place to test the control panel and hydraulic drives. Unfortunately, a hidden leak in the hydraulic system was discovered: the original tubes had to be replaced with new steel ones. Everyone could be convinced of the operability of the box: all speed gears, except the reverse gear, were engaged quite easily, and the reverse gear, after a little work on the switching mechanisms (disassembling and lubricating the safety mechanism), was also engaged. On December 17, new steel pipelines were tested in operation. The onboard clutch drive worked properly, as expected.

- Engine repair meeting

- Inspection of the engine compartment

- Hole in the housing and petrol cistern cap

- Number on the hull, possibly including the serial number of the tank

- Another view of these numbers

- Other numbers on the hull

- Magneto mount, cover open

- Larger view

- Bosch company nameplate

- Repairman pointing finger at problem

- Electrical wires in insulation

- Bosch nameplate with number

- Another Bosch nameplate

- Exploring the device

- General view of the device

- Serial number JGN6R18a

- Another photo of the device

- Gear in casing

- Gear close up

- Vitaly F, repairman and WW2 reenactor

On February 19, 2006, the Panther left the repair bay under its own power for the first time. After a lot of work setting up the ignition system and eliminating minor defects, by Sunday evening the tank went out onto the street and turned around without any problems. However, it quickly became clear that there was a malfunction that prevented the tank from moving independently. During the test run, significant wear of the friction linings of the main clutch was discovered. Troubleshooting requires considerable time, so in the near future all work was aimed at this problem. The first movement of the Panther showed a serious malfunction of the main clutch. To carry out the initial diagnostics, the clutch was disconnected from the control panel and suspended inside the tank on a specially made stand. Incomplete disassembly of the device showed that the clutch is adjusted incorrectly, some of its elements do not work and, in addition, there is a high probability of wear or destruction of the friction linings. Complete disassembly of the inside of the warhead of the tank turned out to be impossible, and a decision was made to remove the clutch from the tank. The upper frontal plate was removed (this required a lot of effort – a number of fastening bolts made of armor steel were completely riveted into their sockets), and the clutch on the winch was pulled out. After this, in accordance with the technical documentation, a special puller (extractor) was made, the clutch cover was removed, the thrust disc was disconnected, the bearings were removed and the discs were removed. The clutch linings turned out to be made of cermets, and although their general condition was quite satisfactory, the possibility of their replacement could not be ruled out. After a lengthy meeting, it was decided to clean the clutch mechanisms (many moving elements were oxidized) and assemble it with the existing discs, “compensating” for their wear through normal regulation. Based on the test assembly results, the adjustment range was considered sufficient, and after complete cleaning, the clutch was assembled and prepared for installation in the tank. The installation of the clutch went without any problems: first it was lifted and laid inside the tank, then, after preparing the destinations and clearing the space, it was installed in its place, followed by assembling the pan cover, tail, etc. The final adjustment showed the reason, from -cause of the malfunction: previous users of the Panther did not know how the Main Friction was adjusted, and tried to compensate for disc wear by rearranging (rotating) the pressure ring lever. As a result, the movement of the clutch pedal while the clutch was correctly adjusted was not enough for it to work properly. Fixing this problem required another week. The clutch was fully assembled and was awaiting a test run; work was being done to eliminate minor faults identified during the February trip and assemble the armor of the tank’s engine compartment. On April 22, 2006, during the day, the final preparations for the test run of the tank were completed. On one of the radiator groups, it was necessary to slightly change the shape of the “new” drainage tube, which interfered with the installation of armor plates. In one of the carburetors, a faulty valve was replaced, and in the cooling system, a defective cotter pin was replaced, due to which the water pump shaft “moved out” of the spline joint. After this, the massive armor plates of the fans were winched onto the roof of the engine compartment. Installing the armored sheets required welding the missing (torn off many years ago) mounting studs. By the evening of April 22, the Panther went outside under its own power for a test run and to clean the repair bay before the Victory Day holidays. The stable operation of the engine and the normal behavior of the main clutch made it possible to carry out a test run of the Panther along the concrete track of the demonstration circle in the remaining time. During the test run, all main driving modes were checked: speed gears from first to fourth, turning right, left, left, in neutral gear and braking. All the mechanisms worked well, and the tank was returned to the repair bay almost at dusk.

To be continued (engine repair at the ZIL plant)

Kubinka Panther tank in cinema and World War II reenactment

In 2006, the Panther, together with another German medium tank Panzer IV from the Kubinka museum collection, participated in the filming of the feature film “Father” about the Second World War. The entire film is dedicated to the feelings of a Red Army officer who, like many others, had a “field wife” during World War II. His legal wife, when he was at the front, during the famine lived with the secretary of the Communist Party, who helped her and the children with the food. The battle of this Red Army commander with the German tanks is shown only twice in the small fragments, where both German Panzer IV and Panther tanks attack the Soviet trenches. Filming took place on the territory of the Kubinka tank training ground NII-38 with the participation of the professional actors and WW2 reenactors. As a result of the debris in the gasoline, the engine stopped working and the Panther went back to the hangars for the restoration. After repeated repairs, the Panther again participated during the holidays in the reconstruction of the battle based on the real events and the famous Soviet film about the T-34 tank. Kubinka Tank Museum archive 2006, photo Sergey K.

- Film “Father” 2006 archives, Kubinka training ground

- Panther and Panxer IV, Roman K in German uniform

- WW2 Red Army infantry reenactors

- Trenches and WW2 Red Army infantry reenactors

- Gunsmith Dmitry and machine gun Maxim from Mosfilm Studio, make-up artist

- Movie camera, shepherd, herd of sheep and imitation tank

- Reenactor Dmitry K and the Soviet ZIS-3 cannon

- Repair team Roman K and Alexander A in replica uniforms provided by Mikhail B

Panther tank at festivals and holidays in Kubinka.

PzKpfw V Panther tank in the old photographs from the Kubinka archives.

Panther tank in the Saumur collection, Loire Valley, France

Before the disbandment of the Russian Central Museum of Armored Vehicles and Weapons and the creation of Patriot Park, Kubinka was Saumur’s friend and the museum brother. The French Tank Museum has not one, but two Panthers Ausf. G and one Ausf. E in its collection, including one in the working condition. The Saumur Panther also participates in the festivals and celebrations held in Normandy, Champagne, the Ardennes and other regions. The most famous WW2 battle and its reenactment is the Allied landings on D-Day in Normandy and Operation Overlord. The Panther tank can be seen in the action also in Saumur on certain dates called “carousel”. You can visit the museum in Saumur from Paris by yourself (the long-distance train with a transfer, then a taxi) or book a private tour. The location of the Museum in the Loire Valley can be seen on the map among the castles and other attractions.

- Saumur tank museum (Loire Valley) entrance

- Germany Nazis, Third Reich tanks and assault guns, artillery

- Saumur tank Museum in the Loire Valley guide and description in English

to be continued